Jantech is always looking for experienced and ambitious individuals to compliment our staff. Jantech offers compensation packages including salary plus overtime, company vehicle, health and disability insurance, 401K profit sharing programs and more.

Careers

If you are interested in being part of a dynamic organization we invite you to apply online today!Current Openings

Please have a look below at our open positions and if interested fill out the application below.

UPS Technician - US East Coast

Description:

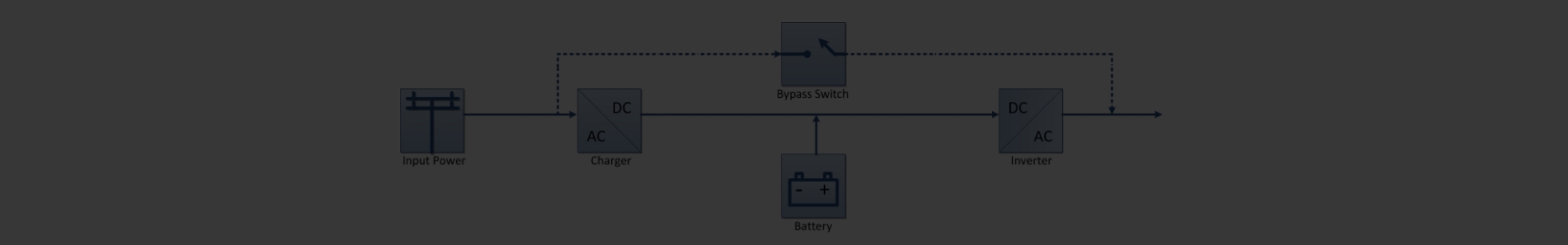

Experienced UPS Field Technician to perform maintenance and troubleshooting of Uninterruptible Power Supplies (UPS) both single and three phase, from all manufacturers and associated ancillary equipment. Entry level candidates also considered.

Tasks include:

- Interpretation of technical documentation including schematics

- Performance of electrical equipment maintenance routines

- Battery system maintenance

- Use and care of electrical test equipment

- Record keeping

- Electrical equipment troubleshooting, primarily UPS

- After hours and weekend work as required

Minimum Qualifications:

- Certification or degree in recognized Electronics / Electricity based curriculum

- Familiarity with use of electrical test equipment (eg) DVM, Oscilloscopes, Load Banks, etc.

- Fundamental understanding of AC/DC theory

- Basic computer literacy

- Clear oral and written communications

- The ability to lift and move equipment with weights up to 75 lbs

Preferred Qualifications:

- A Bachelor’s degree in Electrical or Electronic Engineering Technology or a highly related field

- Minimum of 5 years of experience servicing, troubleshooting, installing and maintaining critical power equipment

- Ability to read and decipher electronic schematics and troubleshoot electronics to the component level

- Factory training, or the equivalent, in the repair and maintenance of multiple leading UPS brands

Hourly Position: Rate is commensurate with experience

Benefits: Benefits package provided upon successful introductory period including paid Medical Insurance for the employee after 90 days employment, 401k after first year, Short Term/Long Term Disability Insurance, Paid Holidays and Vacation.

Location: Although we are always looking for qualified individuals we have an immediate need in

- North Carolina

- New Jersey

- Virginia

Application for Employment

Please fill out the following form, and cut-and-paste or attach your resume, to be considered for future opportunities with Jantech Services

NOTICE TO PROSPECTIVE APPLICANTS: Federal law requires all employers to verify the identity and employment eligibility of all persons hired to work in the United States. This employer will provide the Social Security Administration (SSA) and, if necessary, the Department of Homeland Security (DHS) with information from each new employee’s Form I-9 to confirm work authorization.

All applicants must pass a background screening and drug test before an offer of employment is extended.

IMPORTANT: If, after an applicant has been extended and accepted an offer of employment, the Government cannot confirm that you are authorized to work, this employer is required to provide you written instructions and an opportunity to contact SSA and/or DHS before taking adverse action against you, including withdrawal of the offer of employment or terminating your employment.

Jantech Services is proud to be an Equal Opportunity Employer and Affirmative Action Employer. All qualified applicants will receive consideration for employment without regard to race, color, religion, sex, or national origin.